Repair and reconditioning aren’t a niche add-on, they’re the operational backbone of modern, auditable reuse.

At Octobox this approach has been core since 1978. Containers are designed for repeated use with liquids, powders and granules in mind, and processes were built to keep units circulating rather than being thrown away.

For businesses moving bulk ingredients or packaged product lines, that heritage delivers measurable benefits today.

Here are five reasons why repair & reconditioning should be central to your packaging strategy.

- It gives you demonstrable lifecycle evidence (what regulators and buyers now demand)

Regulation is shifting from aspirational goals to verifiable proof. The EU’s PPWR (Regulation (EU) 2025/40) emphasises reuse and lifecycle performance, not marketing statements. A repair & reconditioning system for reusable IBCs produces the records auditors want – reuse counts, cleaning and service logs, reconditioning histories and provenance data. Those records turn sustainability claims into auditable facts you can include in a Declaration of Conformity and your technical dossier.

- It lowers total cost of ownership when returns are working

Designing for repair means parts can be replaced and units returned to service instead of replaced. Over multiple cycles the purchase price is amortised and your cost per delivery falls. Octobox’s returnable packaging features, fold-flat empties (300 empties in a 20-foot container), stackability (up to five high) and standard pallet footprint, make returns commercially viable and drive per-cycle economics whether you’re moving liquids, powders or granules.

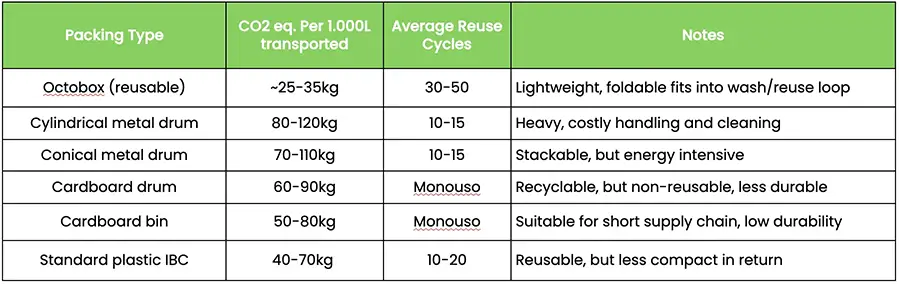

- It reduces environmental impact in verifiable ways

Reconditioning cuts raw material demand and waste. When combined with a robust Life Cycle Analysis (LCA), repair & reconditioning lets you quantify and prove the carbon and material benefits of reuse, precisely the evidence sustainability teams and procurement need to justify change internally. Using reusable IBCs and returnable packaging supported by an LCA is a far stronger, provable sustainability story than one-off recycling claims.

- It fits existing logistics, no wholesale redesign required

Octobox was built for real-world supply chains and multiple product types. Bag-in-box options (500 L–1,250 L) sit on standard 1,140 × 1,140 mm pallets so they stack side-by-side in containers and warehouses, and they work for liquids, powders and granules alike. They tolerate −30 °C to +50 °C environments and can be filled or discharged from the top, bottom or side. This means you can pilot reuse with minimal disruption to handling, racking and container planning, and you can add custom branding and full-surface printing to help with identification and on-pack information requirements.

Interested in RFID, custom branding or printed handling instructions for your flows?

See our Customisation and smart-tracking options:

- It arrives with the paperwork buyers and auditors expect

A supplier who has made repair & reconditioning its business model provides more than a product: Octobox supplies a PPWR EU Declaration of Conformity, a full LCA, validated cleaning protocols and reconditioning records, and can link operational evidence (reuse counts, cleaning logs) to RFID or QR/digital marking if required.

The combination of technical documentation and operational practice removes guesswork for procurement and compliance teams assessing reusable IBCs and returnable packaging solutions.

What this means in practice

If you’re evaluating routes to compliant reuse, start with high-volume flows, especially those that move liquids, powders or granules. Pilot two or three SKUs, capture reuse counts and cleaning logs (RFID makes this simple), and use the data to populate your technical dossiers and your Declaration of Conformity.

Octobox supports pilots with units, cleaning/reconditioning recipes and the documentation you’ll need to show auditors. Custom branding options also let you place clear handling instructions, material and recyclability information directly on-pack, an important practical step for PPWR labelling and buyer checks.

Repairable.

Recondition-able.

Ready.

That’s Octobox.

Want a one-page briefing or a pilot template for procurement and operations?