ASTM D4169-22 Distribution Performance Testing at Assurance Level 3

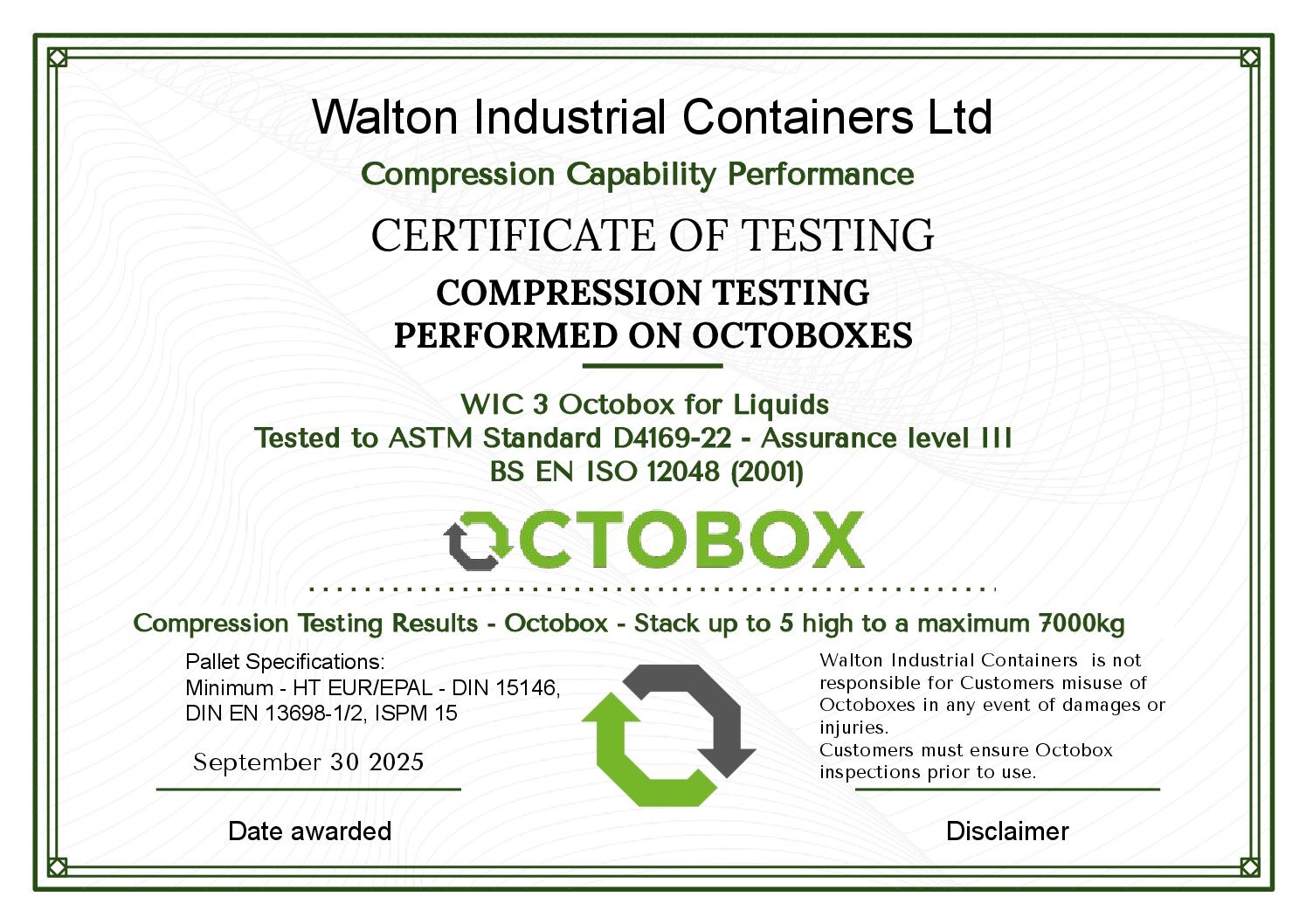

Recently the WIC 3 Octobox IBC for liquids completed formal compression and stacking tests and published the certification and test reports so procurement, logistics and compliance teams can rely on auditable data.

The WIC 3 Octobox was subjected to ASTM D4169-22 distribution performance testing at Assurance Level 3 and to the compression/stacking procedures defined in BS EN ISO 12048 (2001). The tests confirm safe stacking of Octobox units up to five high to a maximum total stack weight of 7,000 kg when palletised on HT EUR/EPAL pallets that meet DIN EN 13698-1/2 and ISPM 15 export treatment. Those are the practical, auditable facts your operations and compliance teams will need when writing technical dossiers or assessing returnable packaging.

What the standards mean for you

ASTM D4169-22 models distribution hazards, vibration, shock and compression, and helps predict how packaging behaves through real-world transport. Running the WIC 3 Octobox through this regimen at Assurance Level 3 gives buyers confidence and evidence the system stands up to standard warehouse and transport conditions. ISO 12048 is the controlled, repeatable compression method used to measure stacking strength; it is the basis for our “Five High / 7,000 kg” conclusion.

Pallet and wooden packaging standards matter because test results only mean something if the load platform is consistent. For the tests the use of HT EUR/EPAL pallets (heat-treated, ISPM 15 compliant) produced to DIN EN 13698 specifications so procurement teams can replicate tested conditions in their warehouses and container loads.

Why these results matter in real-world logistics

Stacking and compression test results translate directly into safer warehouse stacking patterns, more accurate container planning and clearer cost-per-cycle models for returnable systems. Knowing an Octobox can be stacked five high to a defined weight lets operations plan racking heights and storage densities without guesswork, and it helps logistics teams calculate how many full units safely fit in standard container loads.

For teams considering reusable IBCs as part of a circular packaging strategy, the combination of test evidence (ASTM D4169-22 and ISO 12048), a Declaration of Conformity and operational guidance drastically reduces procurement risk.

What Octobox supplies with every tested unit

Confidence does not just stop at a test certificate. For each WIC 3 Octobox the full test report is provided. A Declaration of Conformity referencing ASTM D4169-22 and ISO 12048, pallet and stacking guidance (HT EUR/EPAL, DIN EN 13698-1/2), and easy-to-use operational notes for handling, stacking and refurbishment. Where required, UN-approval details and food-grade cleaning validation are included so compliance teams can attach the documents directly to technical dossiers.

How to use this evidence

If you are preparing technical files or an audit pack, ask your supplier for the test report and the Declaration of Conformity and confirm pallet spec (HT EUR/EPAL) matches the tested configuration. If you need a short, one-page summary for operations or auditors, a downloadable PDF can be supplied which highlights the ASTM and ISO test results and the practical handling limits, ready to drop into procurement and compliance files.

Final note

Tested performance plus clear documentation is what moves a product from marketing claim to auditable fact. The WIC 3 Octobox compression testing to ASTM D4169-22 and ISO 12048, together with the pallet specification and ISPM 15 treatment used, is published in full and available on request for procurement, logistics and audit teams.