PPWR is Mandatory for EU

The EU’s Regulation (EU) 2025/40 on Packaging and Packaging Waste (PPWR) is changing how packaging is judged. Design, traceability, lifecycle proof and reusability matter now in ways they didn’t before. For companies moving liquids and bulk ingredients, the immediate question isn’t “what might change?”, it’s “how do we show compliance with as little disruption as possible?”

Octobox was built for that exact problem.

Octobox have been making reusable IBC solutions since 1978. The Octobox system was originally designed to carry early plastics and today serves chemicals, plastics and food & beverage customers worldwide. This heritage matters, Octobox is not a “fit to meet new rules”, it’s a long-established platform which already produces the documentation and operational evidence procurement and compliance teams need.

Why does that matter under PPWR?

The Regulation prioritises reuse and demonstrable lifecycle performance over one-off recycling statements. A well-run reusable IBC system reduces single-use volumes, simplifies conformity evidence and lowers the number of material tests you must run for multiple SKUs. Octobox delivers all of what is needed in practice. Octobox containers are reusable, refurbishable and designed to be returned and tracked. Real-world use shows up to seven round trips in two years in active return logistics, and because empties fold flat (300 empties in a 20 foot container), returns are economically viable.

Octobox makes the compliance case tangible.

Octobox provides a PPWR EU Declaration of Conformity and a full Life Cycle Analysis (LCA) so you can slot supplier evidence straight into your technical dossier. Material specs are explicit, FSC-certified plywood in the frame, a 70/30 woven polypropylene composition for the bag and external panels, and where customers need it we supply UN-approved variants and validated cleaning protocols for food-grade use. In short, you get the paperwork and the operational model, not vague sustainability messaging.

Operationally, Octobox is built to fit existing supply chains. Octobox bag-in-box options range from 500L to 1,250L and sit on standard 1,140 × 1,140 mm pallets so they stack side-by-side in containers and warehouses. They stack up to five high, perform in temperatures from −30 °C to +50 °C, and can be filled or discharged from the top, bottom or side.

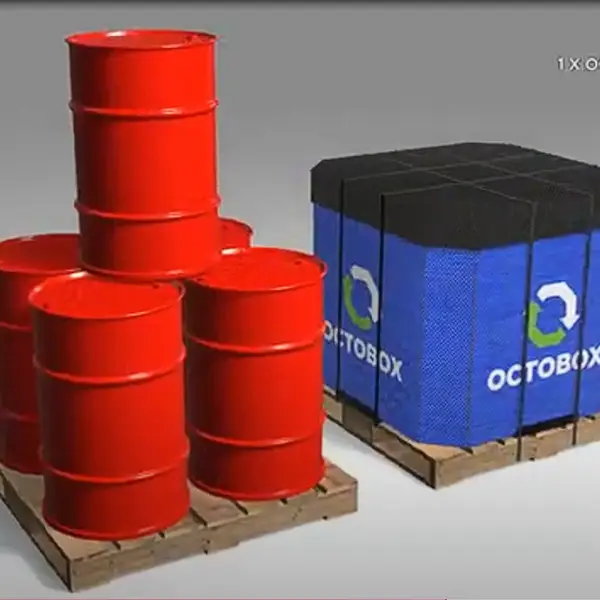

One Octobox replaces roughly five drums by volume. Meaning fewer pallets, fewer movements and a lower cost per delivery when your returns are working. In container terms, you can fit twenty full Octoboxes in a 20 foot container; when folded flat, three hundred empties occupy that same space. Those are the concrete efficiencies which make reuse a commercial decision as well as a compliance one.

Changing packaging under PPWR isn’t only about swapping materials; it’s about predictable documentation, traceable reuse and contractual clarity. To make the transition low-risk you need a supplier who can hand over conformity documents, show cleaning and traceability logs, and support a practical return and refurbishment programme. Octobox does all of these things: conformity evidence is ready, refurbishment pathways are defined, and the Octobox service model is designed to keep containers in circulation rather than in landfill.

Pilot Octobox for Your Reusable IBC

If you’re evaluating routes to PPWR compliance, start with the flows which move the most volume. Pilot a move from drums or single-use pallets to reusable Octobox IBCs for two or three high-volume SKUs. Run the pilot for a full return cycle: record round trips, measure fill and discharge times, and compare transport and handling costs. The data you gather provides more persuasive evidence to auditors and buyers than any marketing claim.

PPWR changes the rules, but it also clarifies what counts as proof. Reusable IBCs aren’t a marketing option, they are a practical, auditable way to meet the Regulation’s intent while improving supply-chain efficiency. Octobox’s decades of manufacturing, clear technical documentation, UN-approved options and an operationally proven return model mean you’re not experimenting with compliance; you’re applying a purpose-built solution which reduces regulatory risk and simplifies the paperwork.

Octobox in a nutshell :

Reusable.

Recyclable.

Compliant.